Frequently asked questions

1. What is paganism?

It is the name given by Christian people in the beginning of our era to the belief in more than one god.

2. What was the recipe for a cocoa drink in the Maya times?

-50 % roasted cocoa beans

-50 % sapote nuts (fruits of the sapodilla) (ponteria sapota)

Add

-crushed corn

-ear flower (cymbopetalum penduliflorum) or xochinacaztli

-vanilla or tlilxochitl

-string flower (piper sanctum) or mecaxochitl

-honey

and if wanted

-achiote

-chilli (capsicum annum)

-allspice (pimienta dioica)

-heart flower (magnolia mexicana) or yolloxochitl

3. When was sugar added for the first time to the cocoa drink?

History tells us that it was Spanish nuns living in Oaxaca in Mexico who added sugar to the cocoa drink for the first time. This happened in the very beginning of the 16th century.

4. Why is the Choco-Story building called De Croone?

5. When was milk used instead of water for the first time in a cocoa drink?

6. How does the chocolate fountain work ?

7. What can be dipped into chocolate ?

8. Is white chocolate, chocolate ?

9. Who does consume most chocolate ?

Norway 9,2 kg

Belgium 9,1 kg

Germany 9,0 kg

Ireland 8,8 kg

U.K. 8,8 kg

Austria 8,5 kg

Denmark 7,9 kg

Finland 6,2 kg

USA 5,3 kg

France 4,9 kg

Australia 4,8 kg

Netherlands 4,5 kg

Sweden 4,4 kg

Canada 3,9 kg

Italy 3,5 kg

Greece 2,5 kg

Portugal 2,- kg

Japan 1,8 kg

Spain 1,6 kg

Brazil 1,- kg

10. Why is Belgian chocolate so popular ?

Subjectively : because the Belgians like good food and that the Belgian chocolatiers have to satisfy their customers.

Objectively:

1. Since last century the composition of chocolate has been regulated by law in Belgium.

2. In Belgium chocolate is finally milled to 18-20 micron, which is below the sensitiveness of the taste buds of the tongue.

3. The Belgian praline, with its outer in nice real Belgian chocolate and its delicate wide choice of fillings, is a delicacy that is appreciated in all countries.

11. Why is the Belcolade chocolate so good ?

- Belcolade produces only for the professionals and does not use other fats than cocoa butter.

- The brand Belcolade is only used for chocolate made in Belgium.

All this results in a specific Belcolade taste.

12. Why is Belcolade not known to the public ?

13. What does the cocoa % on a label mean ?

14. How can you produce chocolate without sugar ?

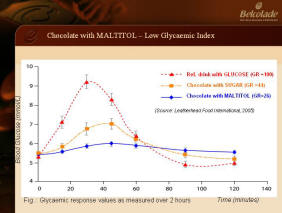

15. What is maltitol ?

Maltitol is a polyol (sweetener category additive E965). It is produced from a disaccharide called maltose. Its sugar intensity is almost equivalent to sugar (80 to 90%) whilst its calorific value is 2.4Kcal/g compared to 4Kcal/g for sugar.

16. What is lecithin and why is it added to chocolate ?

17. How long will dark, milk and white chocolate keep ?

18. What is fat bloom ?

19. What is sugar bloom?

20. How should chocolate be melted (in the kitchen)?

21. Origin of criollo, forastero

The first, called Criollo corresponds to the "cocoa" subspecies and is found in Central America and northern Colombia.

The second type is called Forastero and corresponds to the "sphaerocarpum" subspecies which is divided into two groups.

The Forastero of the upper Amazon and the Forastero of the lower Amazon which is found in the Guyanas.

As the Spanish carried Criollo cacao along the Equator, first to the Caribbean and then on to Indonesia, Java, the Philippines and Malaysia (where local hybrids still show a strong Criollo influence), and the Portuguese brought Brazilian Forastero to West Africa, the variety in type and quality of cacao increased exponentially.

Crossbreeding, both intentional and natural, of Criollo and Forastero varieties, and eventually with their offspring, Trinitario, muddied the waters. Seedlings from one region were transported to others and then back again. One geneotype was no longer necessarily the only tree growing in a specific region. Forastero soon came to dominate cacao-growing regions across the globe. Notable exceptions are Venezuela, small areas in Ecuador, portions of Chiapas, Mexico, Nicaragua and the mountains of Belize. As more growers switched to the lower-quality, disease-resistant Forastero, the benefit of touting origin and varietal was lessened

Manufacturing "advances" furthered the divorce from place. The separation of cocoa butter from cocoa solids in 1828 by Conrad Van Houten of the Netherlands fractured the components of a bean and allowed the content to be manipulated. His innovation of treating the cocoa powder with alkali to make it mix more easily further erased the impact of lineage. Around the same time, the addition of milk solids to chocolate continued the blurring of origin.

However, fine chocolatiers still sought out higher-quality beans well into the first half of the last century. It was only with the move to large-scale manufacturing that origin virtually disappeared. The benefit of product consistency, along with a need for secrecy fostered by unbridled competition, resulted in the conscious anonymity of chocolate. Brand reputation supplanted region reputation as chocolate's origin was hidden from more and more consumers.

It was only recently that chocolate makers have again acknowledged the superiority of certain origins and have begun producing single-source chocolates. The chart above may help simplify an extremely complex mélange of varietal and origin. However, even on a single plantation, the genetic lines between varietals are not distinct. Almost without exception, trees from one origin (no matter how narrowly defined) are a blend. Therefore, the chart above represents only the dominant strain in a given place, recognizing there will be variations.

Predominant Bean Varietal(s) by Region:

| South America | |

|---|---|

| Venezuela | Criollo & Criollo/Trinitario |

| Ecuador | Forastero* |

| Brazil | Forastero |

| Mexico & Caribbean | |

| Mexico | Forastero |

| Grenada | Forastero |

| Trinidad | Forastero |

| Africa | |

| Ivory Coast | Forastero |

| Ghana | Forastero |

| Nigeria | Forastero |

| Madagascar | Trinitario |

| Indian Ocean | |

| Java | Criollo/Trinitario |

| Sulawesi | Forastero |

| New Guinea | Trinitario |

| malaysia | Forastero |

* Arriba beans from a region in Ecuador, while classified as Forastero, are highly valued as a "flavor bean"

22. What does GRAFTING mean?

This graft is done on the young stem of a tree as close to the ground as possible, in order to prevent pods of the cocoa you want to replace reappearing on the trunk.

There are three techniques:

The first consists of taking off the button with which the leaf is attached to the branch. This removal is carried out with part of the bark, which slips underneath the bark of the stem to be grafted. But this technique does not give very good results. A high percentage of grafts do not take if they are not done very quickly.

The second method which gives good results is to fix a piece of stripped branch, to the stripped part of the stem which is to be grafted.

The third method is to insert the end of a branch in the upper part of the stem to be grafted. As the end of branch inserted comprises many "buttons" the results obtained are good.

The technique of grafting makes it possible to change from one type of cocoa to another, more disease-resistant type, giving bigger yields or better quality cocoa.

23. Moniliasis

There is another called "mancha negra" but it can be combated by selection of the types of cocoa planted, because certain varieties are resistant to this fungus.

This is sadly not (yet) the case for moniliasis.

It is a very serious disease which is spread quickly by the spores of the fungus which are carried on the wind.

In Costa Rica most of the cocoa crop was destroyed by this disease.

It made its appearance in Tabasco, but was fought effectively. Only around 500 ha of the 44.000 ha cultivated are currently contaminated.

How do you recognize moniliasis?

1. deformation of fruit less than 3 months old

2. coffee coloured spots with irregular edges on fruit more than 3 months

old and/or aqueous rotting of the interior of the fruit

3. premature and non-uniform maturation

4. a white powder appears on the contaminated fruit

What can be done to stop the spread of moniliasis?

o make the cocoa-plantation clearer. Less shade

o systematically remove all the rotted fruit

o install drainage

o fertilize

o renew the plantation and maintain it well.

24. Trinitario

One is the replacement after a cyclone of the destroyed Criollo trees, by Forastero trees. Some Criollos would have survived and formed a hybrid with the Forastero.

Another explanation is that the replacement was done by a hybrid developed in a lab.

A third version, which we heard in Venezuela is that the Island of Trinidad, after being hit by a cyclone, was populated with cocoa seedlings coming from the Orinoco region of Venezuela where there was an existing hybrid of Criollo and Forastero. This hybrid took the name Trinitario, when it was exported from Trinidad.

This seems to us the most credible explanation.

25. Why do only 2 to 3% of flowers become pods?

When the pollen of the cocoa tree is capable of fertilising its own flowers, the cocoa tree is said to be " auto-compatible ".

On the other hand, when the pollen of a cocoa tree is not capable of fertilising its own flowers, the cocoa tree is said to be " auto-incompatible " and its auto pollinated flowers do not become pods, they wither and die.

Two auto-incompatible cocoa trees can exchange their pollen and fertilise flowers if they are " inter-compatible ".

But this is not always the case.

" Auto-incompatible " trees are not in fact always compatible between themselves. They can be " inter-incompatible ".

Leaving aside all incompatibility problems, the small number of pods that the tree produces - a few dozen - bears no relation to the thousands of flowers that are to be found on its trunk and its main branches. Why?

In order for a flower to develop into a fruit - a pod - it must first be pollinated and then, not only visited by insects carrying pollens, but compatible pollens.

In fact, nearly 60% of the flowers are never fertilised. These flowers die and disappear.

Other flowers are only partially fertilised, the visiting insects not having supplied enough compatible pollen.

A fruit then begins to develop that does not continue its development.

It atrophies and dies. This insufficiency in pollination affects a large number of fertilised flowers.

In general, less than 5% of the flowers initially produced by the cocoa tree become "cherelles".

But up to 90% of the "cherelles" can still disappear: before they are three months old, they dry and blacken. This phenomenon is called "cherelle wilt".

This drying or "wilting" of young fruit is brought about by the plant itself, which tries to limit the number of pods to an amount it can successfully support.

The pods become mature after five to seven months of development, when they have overcome the obstacles of incompatibility, insufficient pollination, wilt, disease and predators.

26. What are the ideal climatic conditions for the Cocoa Tree?

The soil should achieve a compromise between two sometimes contradictory demands: ensuring good water retention on one hand and being well-drained and therefore well aerated, on the other.

Ideally, rains should be abundant but above all spread across the entire year. Rainfall of 1500 - 2000 mm per year is favourable if the dry season (less than 100mm a month,) is no longer than three months

A hot and humid atmosphere is indispensable to the cocoa tree. Seasonal temperature fluctuations affect its growth and development. It requires a rather high temperature with an average maximum of 30 - 32 ºC and a minimum temperature of 18-20 ºC. The absolute minimum must not be below 10 ºC. These climatic conditions generally occur between the 20th parallel north and the 20th parallel south.

27. Fermenting the beans

With the pod cut open, the beans and their mucilage have to be separated from the rest, eliminating any damaged, malformed or mildewed beans.

The fresh beans, enveloped by their mucilage, must constitute a sufficient mass into which air cannot penetrate because everything must ferment.

Fermentation, or rather successive fermentations, will make substances responsible for future aromas develop in the mass.

Good fermentation brings the temperature of the mass up to about 45 °C. Substances are produced which penetrate the bean and, together with temperature, play their part in killing the embryo.

From a whitish (Criollo) or mauve (Forastero) colour, the beans become progressively brown.

Beans which are not submitted to high enough temperatures, do not ferment. They take on a slate grey appearance and do not taste as good.

To avoid this, the mass of the beans must be stirred regularly

In the first phase, fermentation starts.

Alcoholic fermentation occurs in the second phase where no air must be present.

In the third phase, acetic fermentation demands the air be present once again.

The length of fermentation varies according to the type of cocoa tree.

Normally four to six days are necessary for Forastero and Trinitario types, whereas fermentation of the Criollo takes only two or three days.

28. Drying the beans

The transformation of the beans continues during drying which causes the inside of the bean to become browner. If drying happens too quickly, the oxidation reaction becomes too limited and the acetic acid will remain trapped, giving excessive acidity and changing the taste of the chocolate made from the beans.

If drying occurs too slowly, mildew can appear, whereas if it is too fast, the cocoa produced will be too acid.

Heating should be gentle for the first 48 hours in order to prolong oxidation

Beans dried in the sun are less acid than those dried artificially.

29. What is the difference between lavado, beneficiado and fermentado cocoa?

The beans are washed, not fermented.

Beneficiado:

The cocoa beans are not washed and are left to ferment for 1 to 2 days.

If they are sun dried, which is the best method, they will have a brown colour.

If they are dried artificially, they will be purple coloured.

In addition, sometimes they are not washed and are left to dry in the sun or artificially.

Fermentado:

Previously, the beans were fermented for ± 3 days for the Criollo and ± 5 to 6 days for the Forastero and Trinitario.

They were then washed, sun dried and coated with cocoa butter.

That gave them a sheen and made them easier to preserve.

Today they are fermented for 2 days, carefully covered to avoid air entering.

They are then fermented for another 4 to 5 days, being changed every day to another container.

Except for the Criollo where fermentation lasts only 3 days.

30. How many types of cocoa are there?

Theobroma cocoa is one.

Theobroma bicolor is another.

The Theobroma cocoa species is composed of 14 groups of cocoa.

One of these groups is genetically very homogeneous, that is the Criollos.

The 13 other groups vary genetically from one group to another; they are the Forasteros.

The Theobroma bicolor species is also known as "pataste" in Mexico and is a rarely grown species.

The tree is tall and is sometimes used in cocoa plantations to provide shade.

It is to be noted that the cocoa pod or the fruit of the pataste grows at the end of the branches and not on the tree trunk, as is the case of Theobroma cocoa.

In addition, the husk is hard. In terms of consistency it is similar to a coconut.

The beans are bigger and flatter than cocoa beans.

Pataste pod

Pataste pod

Cut in half

Cut in half

31. Cocoa qualities and categories

Quality

For the world market, the quality of a batch of cocoa is determined on the basis of 3 criteria:

- The water content, which must be 7%

- The graining (number of beans per 100 grams) which must be 100 beans or less

- The cut test, which determines the level of fermentation (colour of the beans) and the number of defects, such as mouldy or moth-eaten beans, etc.

However, there is absolutely no measure or even indication of the aromatic quality of batches.

Categories

The world market divided cocoa batches into 3 categories:

- Bulk, or current cocoa. This represents 90% of the market and is sold at prices determined on the stock markets in New York and London.

- Fine Cocoa. Quotas are determined by an ICCO (International Cocoa Organization) committee, which takes more account of the relationship between supply and demand than the real aromatic quality of the cocoa. This type of cocoa can be sold at up to twice the market price.

- Rare Cocoa or single-origin cocoa. This type of cocoa is in great demand and is traded over-the-counter.

Bulk producers

Bulk cocoa is produced on 3 continents:

- Africa produces 70% of the world's production, with the Ivory Coast alone accounting for1 405 000 tonnes in 2002/2003: it is the largest production in the world and cocoa from Ghana (736 000 tonnes), which proposes the best bulk, is sold above the market price.

- Asia markets above all cocoa "butter", intended for the extraction of cocoa butter. Indonesia produces 415 000 tonnes, sold below the market price (except for Java which is a rare cocoa) and Malaysia whose production is declining.

- Latin America is the bulk producer of the USA, with Brazil: 163 000 tonnes, but whose production has declined significantly owing to contamination by "witches broom", Mexico and Sanchez cocoa from the Dominican Republic (which represents 80% of that country's production).

Producers of fine and rare cocoa

The world of cocoa considers that there are few main origins of fine and rare cocoa. These are, from West to East:

- Ecuador, with its Nacional variety (only 30% of the country's production) which is well known for its hints of flowers: the famous "Arriba" aroma. It is necessary however to be vigilant since mixtures with less aromatic varieties, such as the CCN 51, can occur. The market sees only categories (SSS; SS etc.) based solely on the graining and the number of defects and not the aromatic quality.

- Venezuela has mainly 2 cocoa producing regions out of 8 which produce fine cocoas. These are the Puerto Cabello, with the villages of Chuao, Choroni and Ocumare and the Sur del Lago, with porcelana type cocoas, a cultivar of criollo, typical of only this region in Venezuela, characterised by full aromas of honey, caramel and fresh nuts.

- The Caribbean: all the islands from Trinidad to Cuba produce cocoa with hints of tobacco, wood and dried fruit. The Dominican Republic which produced non fermented cocoas, became aware a few years ago of the potential of its varieties and its land identical to those of neighbouring islands. Today, this country markets 20% of its production as "Hispaniola" fermented cocoa.

- The archipelago of Saõ Tomé e Principe is the place via which cocoa entered Africa in 1822. Old Forastero Amelonados which produce a subtle cocoa aroma are still found there today.

- Madagascar is renowned for its slightly sharp and fruity cocoas of the valley of Sambirano. Demand far outstrips supply. As a result even ordinary cocoas of this origin are sold as fine cocoas.

- The Island of Java, in Indonesia is planted with old criollo, which are very poular for their peaty or spicy hints; they can be sold for up to 3 times the market price.

- Papua New Guinea has volcanic soils, which are very suitable for the production of fine cocoas, similar to those of Java.

32. No Sugar Added Chocolate & Sugar Free Chocolate

In most all chocolate types sugar is used as a sweetener and a bulk ingredient.

ð Normal sugar (chemically known as sucrose or saccharose) has a clean sweet taste. The sweetness of sugar is often referred to as the standard with a value of 100.

ð In a typical chocolate composition the % of sugar is anywhere between 30 to 55 %. And this is the same for dark, milk or white chocolate. This high amount implies that sugar is also an important bulk ingredient.

In the No Sugar Added (NSA) chocolate all sugar has been replaced with maltitol. Maltitol is a polyol (or sugar alcohol). It is also used in crystalline form and has a sweetness that is very close to sugar (sweetening power of 90). Since also many of the other characteristics are similar to those of sugar (like hygroscopicity, hardness, etc…) it can be used in the same quantity as sugar.

Difference between sugar free and no sugar added.

Sugar belongs to the chemical group of carbohydrates. To the same group belong also maltose, glucose, fructose, lactose, etc… These mono- and disaccharides are referred to as sugars.

Based on the upcoming EU legislation a product can only be called sugar free if it contains less than 0.5g of sugars per 100g of product.

All of these sugars also occur naturally in ingredients. Full cream milk powder e.g. contains: around 38% lactose. Cocoa

To understand the explanation it is necessary to note the difference between dark, milk and white chocolate. The table below represents the main components of each chocolate type:

No sugar added milk or white chocolate can ever be called sugar free, due to the presence of lactose sugar from the milk powder.

| Dark | Milk | White | ||

|---|---|---|---|---|

| Cocoa mass | Provides very little sugar (< 0.5%) | |||

| Cocoa butter | fat | |||

| Sugar | Provides sugar | |||

| Powd. milk | Provides lactose (a 'sugar') |

Since diabetics have problems to regulate the glucose level in their blood, the consumption of carbohydrates (type of carbohydrates and quantity) are of particular importance to them. A lot of diabetic people will prefer to eat chocolate with no added sugar, even though the GI of normal chocolate suggests that it is also not so bad.

33. The origins of Belgian chocolate's enviable reputation

1. Subjective:

Belgian citizens are lovers of fine foods. The basic chocolate ingredients have to be of an outstanding quality.

2. More objective:

a. Stringent chocolate composition regulations began to be applied in Belgium a long time ago.

The first such regulations were ushered in back in 1884: all products featuring the name chocolate had to contain at least 35% of pure cocoa.

The composition was provided with a legal setting in1924. (Black) fatty chocolate has to contain 45% cocoa, 50% of sugar and 5% of miscellaneous dry products.

b. Grinding

Chocolate in Belgium is ground down to 15-18 microns, as the tongue can sense grains 18 microns in size or over. This avoids having a grainy taste in the mouth when the chocolate melts on the tongue.

c. Choice of beans

According to tradition, Belgian chocolate makers have always used high-quality cocoa beans. The price does not come into it: they are selling quality chocolates.

A company like Côte d'Or, one of the splendours of Belgian chocolate-making, has definitely helped to define the taste of Belgian chocolate over the years.

d. Praline

A nice-to-have, easy-to-eat product.

The taste may be adapted thanks to various types of fillings.

Neuhaus invented this product in Belgium in 1912.

Pralines are now recognised as being typically Belgian.

Pralines have definitely helped to enhance the enviable reputation of Belgian chocolate.

3. Other factors that may have contributed

a. The very same Neuhaus and wife invented the tuck-in-end box in 1915, thereby improving the packaging format and making the chocolates easier to carry

b. Basile Kestekidès, the nephew of Leonidas' founder, invented the "manon" in 1935. This large white chocolate-coated praline certainly helped to promote the demand for white chocolate with a mouth-wateringly milky taste.

c. The Leonidas Company's first shop with an open front was launched in 1936 on boulevard Anspach. This along-the-street sales concept marked the beginning of the Leonidas success story, and, thanks to a reasonably priced quality product, helped to spread the word about the virtues of the praline in particular and Belgian chocolate-making in general.

34. Dunking biscuits in chocolate in Spain

The mosaic can be found in the ceramics museum in Barcelona.

It is therefore logical that we found the information we were looking for in this town.

We were told that

- In Madrid, it was "churros" that were dunked in cocoa. Moreover, it is still being done today in Spain.

- In Majorca, it was "ensaimadas", prepared with lard called "saïm" in Arab. This speciality is presumed to date from the Arab invasion of Spain.

- In Barcelona, it was "melindros", a kind of sponge cake biscuit, but lighter and a little more compact.

35. Rainforest Chocolate ?

These chocolates are made exclusively from "organic" and "Rainforest Alliance" certified beans originating in this country.

We are very keen on this certification because it goes far beyond the traditional simple fair trade concepts.

The "Rainforest Alliance" label is the guarantee:

- that the cocoa is grown in a way that is compatible with protecting the tropical forest;

- that growers obtain a higher price for their cocoa production and have access to training;

- that the living and working conditions of workers are improved, that they are correctly paid and that their working conditions are acceptable and accompanied by health care and that they have access to education;

- of the constantly improving quality of cocoa products.

36. The origins of the praline

"Pralinage" is used in agriculture to describe an operation which consists in coating the roots of a young tree that is about to be planted or seeds that are about to be sown with a thick mixture of soil and manure to protect them against parasites.

37. Botanical information about cacao

The tree belongs to the Theobroma genus.

Other plants in the Sterculiaceae family include the Guazuma and Sterculia.

The Theobroma genus covers 22 species including :

Theobroma bicolor or pataste

Theobroma grandiflorum or cupuaçú

and, first and foremost, Theobroma cacao.

Theobroma cacao has 2 subspecies:

Theobroma cacao ssp.cacao = Criollo

Theobroma cacao ssp.sphaerocarpum = Forastero.

Mention is also made at times of

- cultivar : which means variety

- clone : which is a copy

- hybrid : is a cross-fertilisation.